MIT Lab Machines Print Furniture in Liquid 3D Space Gel Super Fast

/MIT's Self-Assembly Lab researchers recently created a new kind of 3D printer that creates large items very fast. Instead of layering thin bits of material atop, again and again, this new technology process pushes the material out like a caulking gun or toothpaste. This creates a much more structurally sound object that can withstand greater pressure and weight.

"There are a couple of reasons why the properties aren't so good," he added. "Nearly every printing process utilises layers, and those layers degrade the structural property of the material compared to a consistent material all the way through."

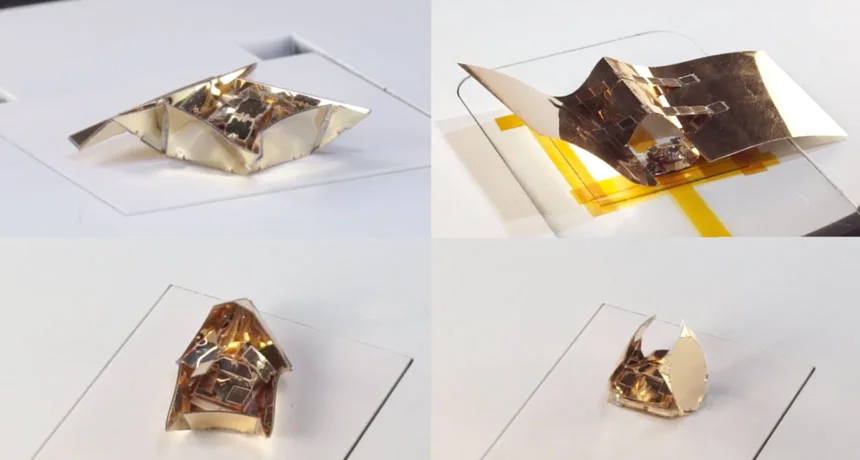

Collaborating with US furniture company Steelcase, this new 3D printing method is called Rapid Liquid Printing. Another unique feature is that the material is injected into a gel which holds it in place while being printed. This enables the freedom to construct forms that 2D layering kinds of 3D printers just cannot match. You could say this is a true 3D printer because it actually prints in 3D space and very quickly too.

"Most of the time we can only print centimeter-scale structures, and for furniture, it's unfeasible," said Tibbits.

"In the beginning, we started with this question: could you print furniture in minutes?" lab director Skylar Tibbits told Dezeen. "If you look at printing from that perspective it forces you to think about it in a completely different way."

The 3 unnecessary limitations of other 3D printers: speed, scale, materials.

Rapid Liquid Printing allows the robotic aperture to draw freely in 3D space, constrained only by the size of the tank.

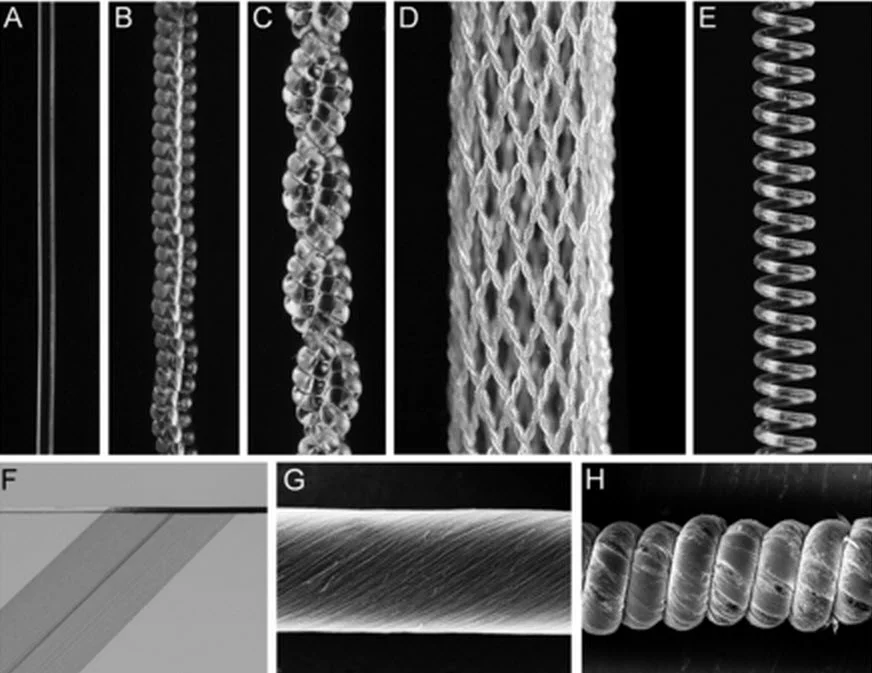

They tested different plastic, rubber, and polyurethane compounds that each remain liquid until mixed together with another chemical to cure when printed. So, using zig-zag and/or intersecting latices of these materials, a wide variety of furniture and items can be made.

Watch it in action here: http://www.christopheguberan.ch

Examples of practical applications for this technology include custom sized furniture to fit unique project needs and even to manufacture automotive, aerospace, and architectural components.

Basically, you're limited to your imagination.